The Octagon House in Stillwater, Oklahoma

The

Chris and Lydia White Octagon House is located at Range Road and 19th

Avenue.

About Chris and Lydia

About the Octagon House and How it was Built

Roof,

Walls, Curtains, Doors, Heating/Cooling,

Cost

Inside Pictures

Family

Tree, Chandelier

Octagon House News

Chris and Lydia Travel Pictures

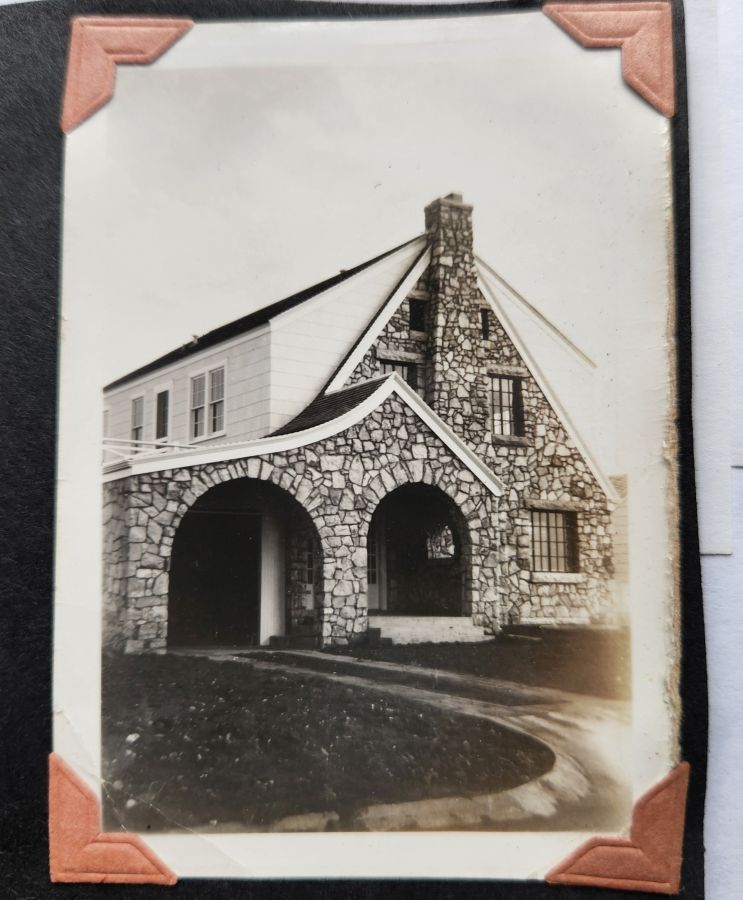

The Octagon House on the White Pony Farm

The Octagon House built by

Chris White

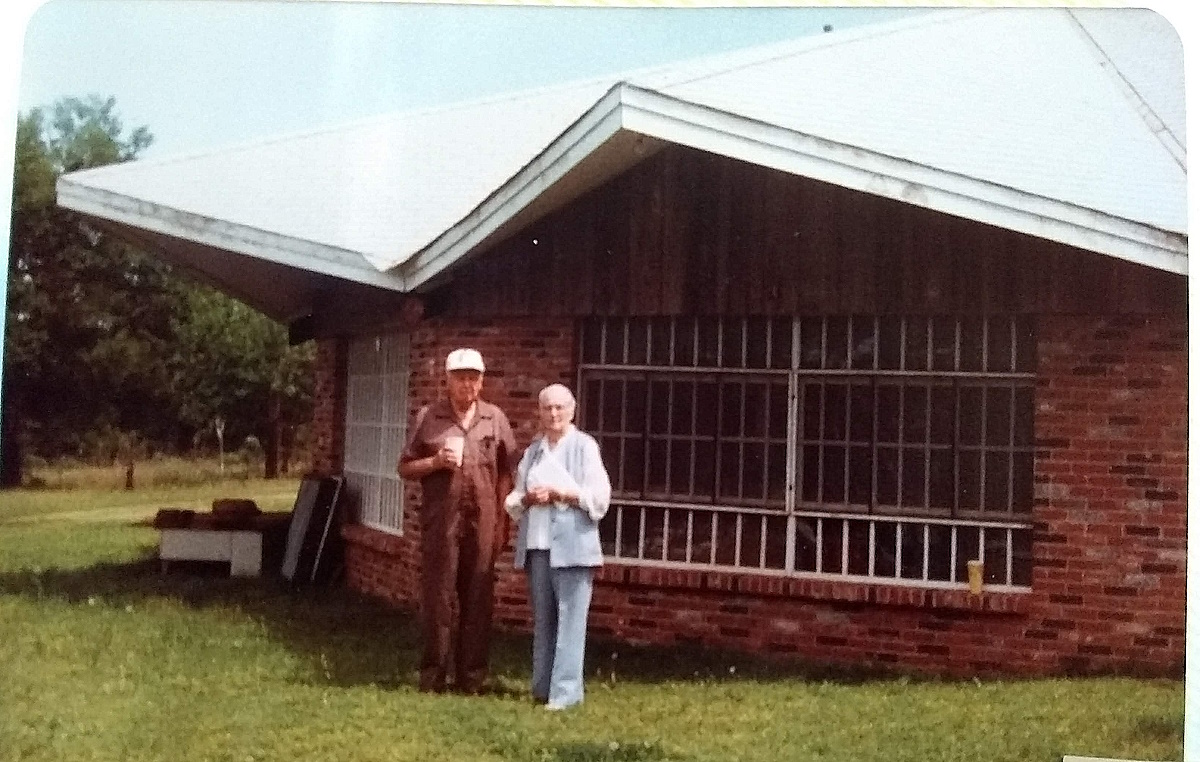

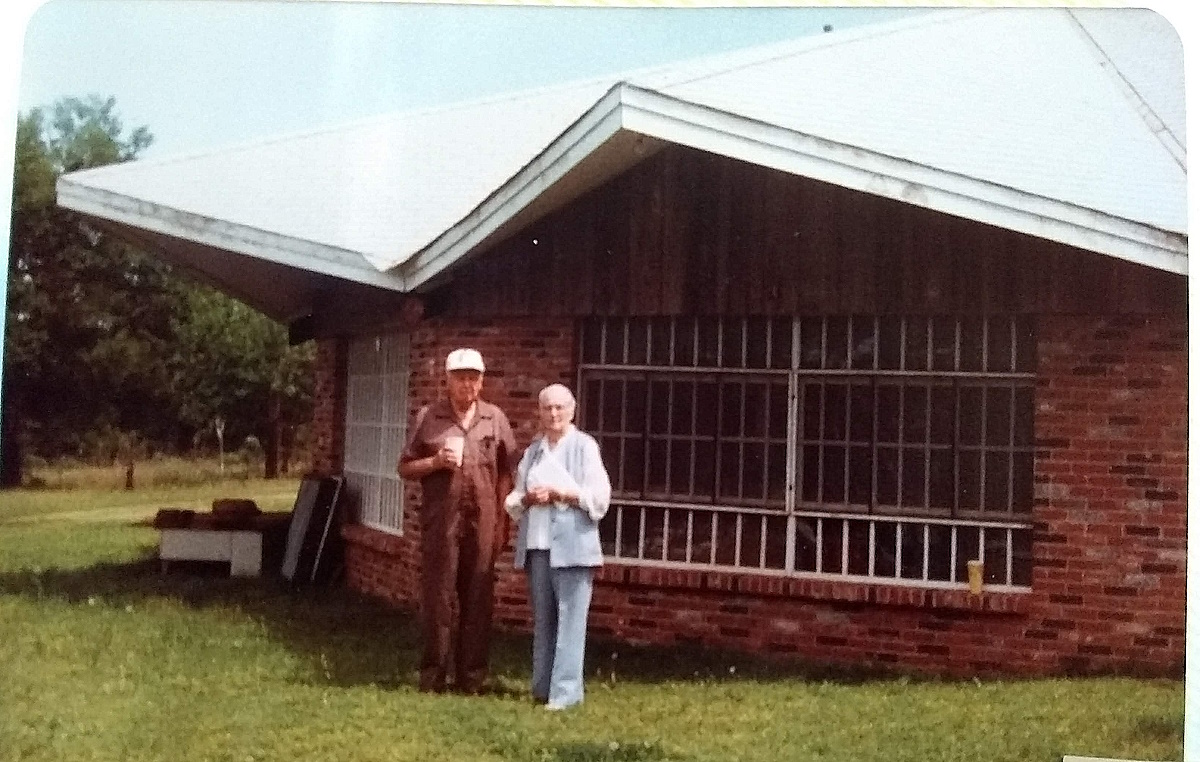

Chris and Lydia

Chris and Lydia White

Chris White (1903-1993) and Lydia Bright White (1905 -1983)

1927 - Chris, 24 years old earned his BS degree and married Lydia Bright

1937 - Chris, 34 years old earned his MS degree in 1938

1927-1938 Chris was Vocational agriculture teacher at Kingfisher and Helena Oklahoma

1938-1968 (30 years) Chris was Oklahoma State University (OSU) Instructor, Assistant Professor Agricultural Education.

They lived at 153 S Melrose Drive - A 7 bedroom, 4 bath, 2,800 square foot house that Chris built.

1960s -

Chris and Lydia traveled alot. See pictures below.

1968 - Chris retired at 65 years old and began working on the Octagon House. He staked the location on a high knoll of the 40-acre tract of land.

1976 - Chris was 73 years old when they moved into the octagonal one-story house.

1977 - Chris and Lydia 50th Anniversary and family reunion to see the house

Back to top

About the Octagon House

This information is from the news articles below.

1,630-square feet

2 bedroom, 2 full bathrooms

Built from recycled and salvaged materials. Chris White takes justifiable pride

- to some what would be an enviable pride of accomplishment-in telling where the

parts of the house came from.

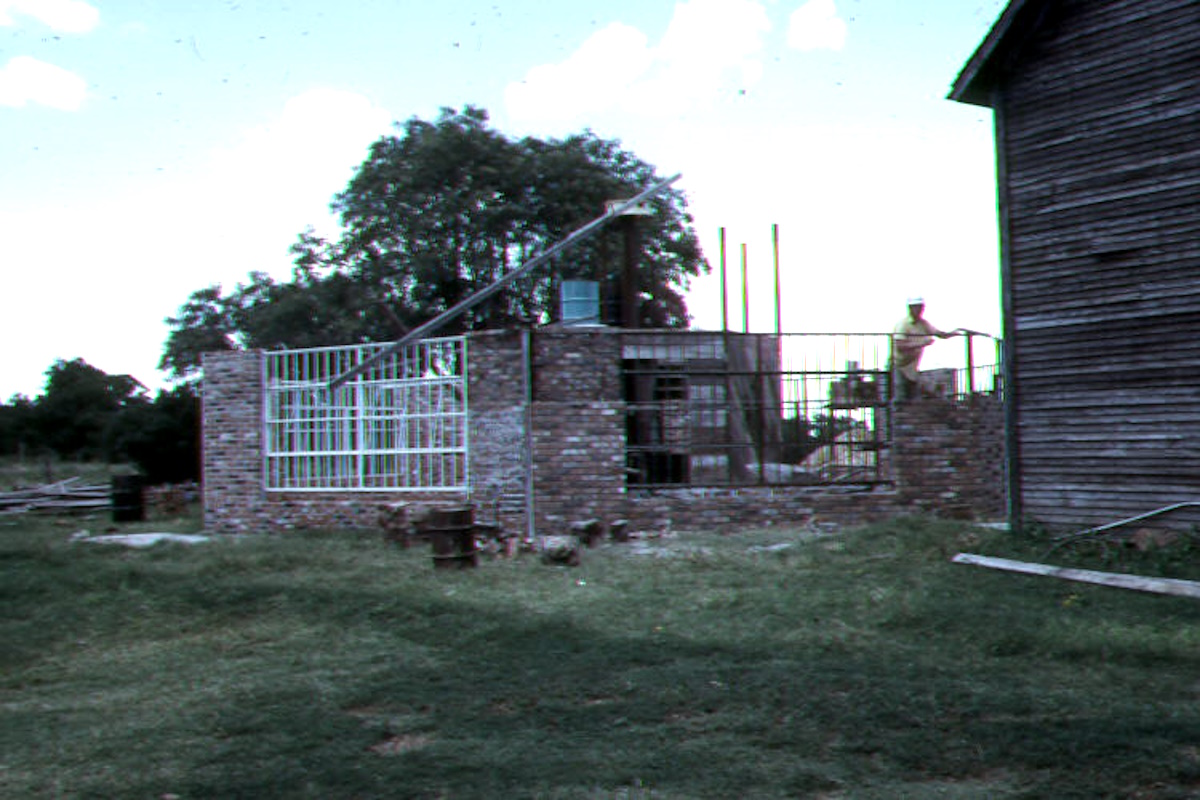

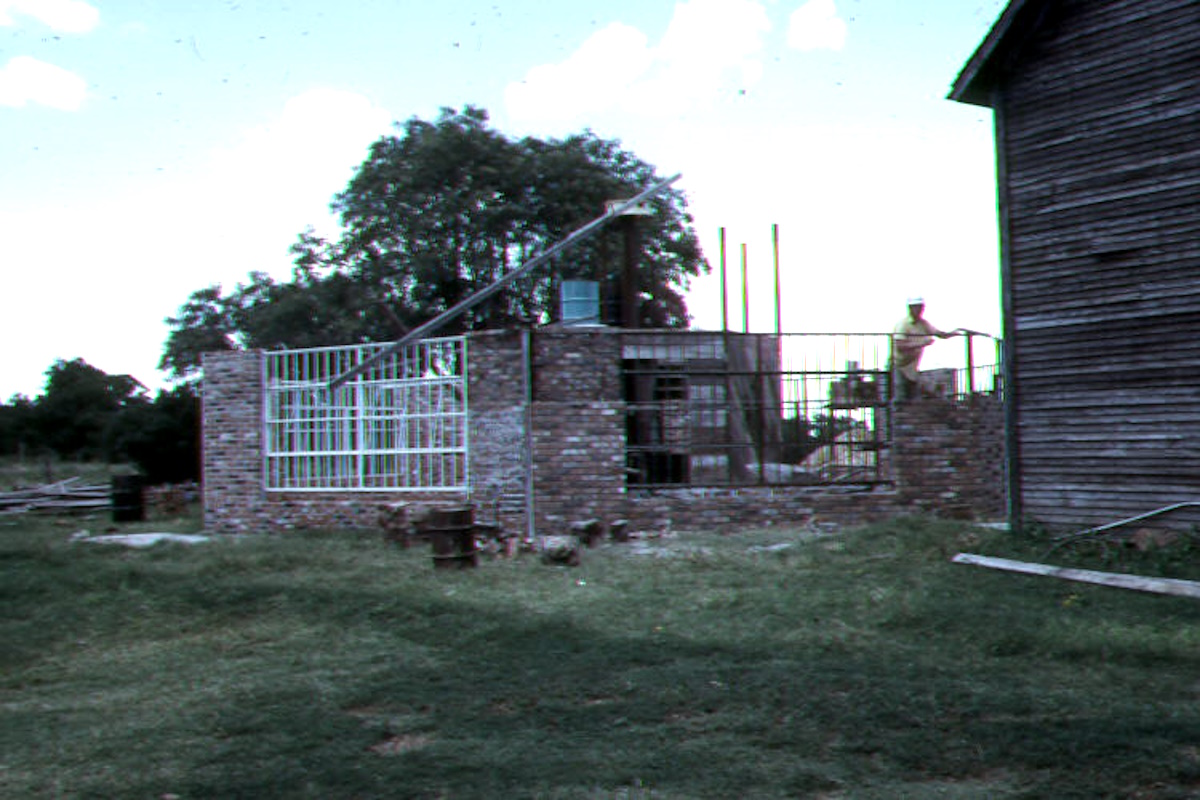

How it was built

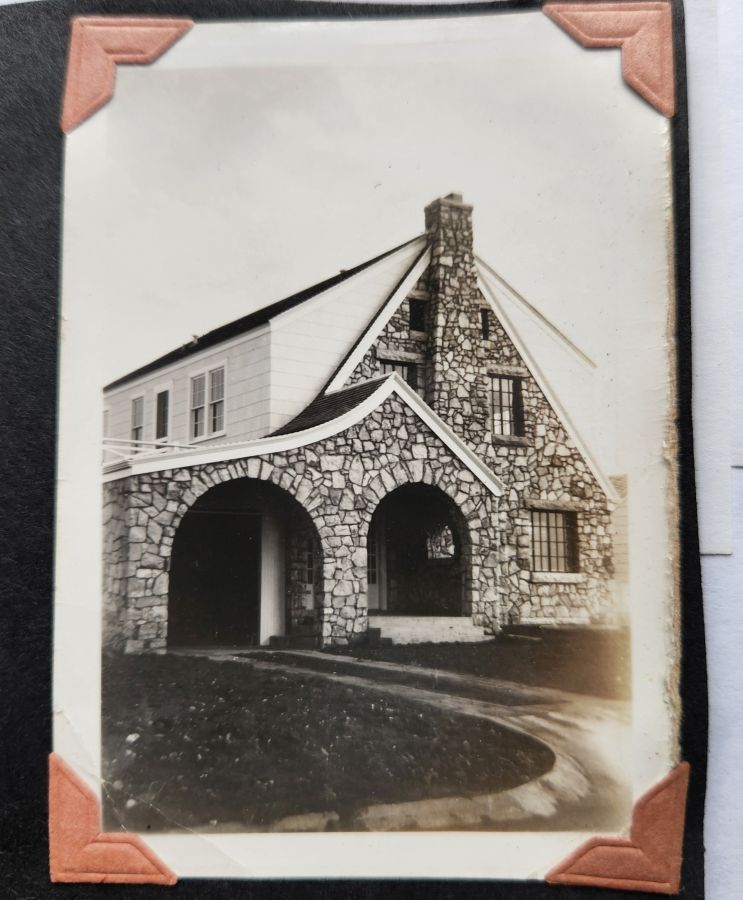

"There were no plans or blue prints, other than what was in my head," White said.

White said he never drew out any of the plans other than some rough sketches on brown wrapping paper now and then. This proved to be a handicap when seeking estimates from builders or contractors.

"They wouldn't even talk with me about doing part of the work without a blue print. I finally found a mason who did some of the brick work, and got me started, and I had help at different points along the way." In essence, however, the home was not only the brainchild of White, but was physically constructed by the couple.

The "blue prints" use to

build the house

.jpg)

Two bedrooms and two

bathrooms

.jpg)

There was no pre-scheduled completion date, and he stresses, no hurry.

Laying out the dimensions and design of the eight-sided house was no trick for White. Drawing upon 70 years experience he used what he called "common sense barnyard arithmetic."

A stake was driven in the center of the area where the house was to be built. From this point White determined the four directions, true north, south, east and west, and using binder twine 24 feet long, lo cated stakes at these points on the directional lines, making the house 48-feet wide.

He then divided the distance be tween each point, and again measuring out 24 feet from the center state, arrived at a perfect octagon, establishing the eight corners of the house. At these points, using a post hole digger, White dug down to solid rock.

In each hole he put a section of 3-inch oilwell drill stem as supports for the house, and then poured a concrete foundation anchoring the drill stem which sets on solid rock. He did the same in the center of the house, using a section of 12-inch pipe which forms the peak of the house and to which the rafters from the 3-inch drill stem are anchored.

The inner core of the house is also octagonal. The dimensions were arrived at in

the same manner as the outside walls, by measuring 10 feet from the center,

along the same divi sional lines, creating a 20-foot octagonal core which

contains two bathrooms and a storage room.

Made from all recycled

materials. 8 utility poles and 12-inch steel pipe.

Roof

of the 8-sided house

The supporting members of the roof are eight utility company poles

(cost $5 each) and a 12 inch diameter steel pipe.

There are eight different gables: One is sheathed in the reclaimed siding from an old barn. Another is corrugated metal. Another is lap siding. One is fiberglass, and so on.

No two are alike because the diameter of the utility poles may vary as much as four inches, one from another, all had to be individually hand-carved when they reached the center of the house. Failure to do so would have created an unacceptable humped effect on the outside roofing surface.

The 12 inch steel pipe which is in the exact center of the house can be seen supporting the steel wheels on which the beams are resting.

And, each of the eight gables of the unusual house are built of different material the Whites collected over the years.

Rafters used to form the cathederal ceiling and support for the roof are old electrical highline

The roof on the octagonal home forms eight triangular folds, each supported by a 10 to 12 inch diameter utility pole (salvag ed). Weight of each massive poles is, in turn, spread out on three vertical steel pipes. Eight in the outside brick walls, eight in the inside walls of the bathrooms. The third support point is at the center of the house. It is a single 12 inch diameter pipe, filled with concrete and reinforced with vertical steel bars.

On this center pipe, all eight poles have been brought together like logs in an Indian tepee. Here they have been chiseled to fit the peak of the house. Around each end is wrapped a band of steel two inches wide and a quarter-inch thick welded to the center pole, anchoring the roof to the vertical 12-inch pipe which sits in a concrete mass beneath the floor of the house.

In the same manner, straps of steel have been wrapped around the utility poles and welded to the other two vertical sup ports holding them snugly in place. In all, there are eight utility poles fastened with welded steel straps to a total of 17 steel pipes.

The hundreds of angles that had to be cut for roof supports were carefully

executed to give smooth, accurate roof lines. The same is true of the walls and

partitions.

Walls

Walls required a few thousand used bricks and Interior gypsum drywall sheeting from construction sites where damaged pieces were discarded.

Chris White personal unique method of insulation carries reclamation almost to a zenith. Inner and outer walls are insulated with salvaged expanded ureathane plastic foam which White ran through a hammer mill to make it granulated, which he then poured into wall cavities.

Feeding a variety of discarded "styrofoam" shipping containers of the same or similar material into a tractor powered hammermill, he extracted a feed bin full of weightless white fluff.

After checking with friends on the campus who assured him of the insulation value, he poured the pulverized and recycled styrofoam into the wall cavities.

"Before going into the hammermill it had very little weight," Mrs. White said. "After it was pulverized it was just a big quantity ... weighing practically nothing."

Because styrofoam is generally considered a by-product of the petroleum industry, manufactured from what otherwise would be a waste product, the further step of reclamation achieved by White and his hammermill from discarded scraps carries the process of recycling about as far as one can go. At this point, the insulation material has found a permanent resting place, and one in which it can provide a year around service.

For people not familiar with farm machinery, at least with vintage farm machinery, White explains that hammermills were used on most farms years ago to grind feed and chop up roughage for livestock. "All farmers used to have one, but today it is less trouble and cheaper to buy feed already prepared. You rarely see one of these anymore."

Chris White used an ancient antique Hammermill. You feed scrap “styrofoam" packaging and Knife blades churn the chunks to a fluffy consistency then fanned, or blew it, through the chimney-like pipe at the top of the hammermill. In a few minutes the bin at the left was completely filled.a

Windows

There are 16 sets of 5x10 foot steel casement windows.

These were purchased without the glass for $4 each when OSU buildings were demolished on the campus. 16 x 4 = $64 for windows.

The windows contain more than 1,000 panes of glass. The glass to fill the panes was purchased for $50 from a greenhouse nursery that went out of business.

"Glass for a green house is stronger, more hail resistant, and easier to work

with than regular single strength glass," Mrs. White comments. "Until we started

replacing panes, I didn't know there was so much difference in glass. It all

looks the same." She adds that it was more work to chisel out the old putty from

the steel frames than it was to install fresh glass, but like her husband, she

too, thrives on the sense of accomplishment for which the home is an exhibition

piece.

Curtains

Insulated drapes / curtains for the windows came from a Holiday Inn in Kentucky which was being renovated.

Doors

Two of the doors complete with all hardware were salvaged from a demolished OSU building at a cost of $10 each.

Heating / Cooling

Dual thermostats for heating and air conditioning

A wood burning fireplace heats most of the living area.

Another wood burning cast iron stove in the attic ducted to the central air conditioning system provides a heat recirculation pattern to bring warm ceiling air back to floor level.

"With a single log burning, and by turning on just the fan of the central air unit, heat from this stove is vented throughout the house. With one log, we can take care of all but the coldest days."

Cost

A contractor offered to build the house for $55,000.

Chris White estimated the total cost of the two-bedroom, two baths and combination kitchen-living area at house around $14,000, not counting his labor.

Chris White was able to hold down costs of what he calls his "eight-sided wonder" by using material he and his wife had collected during 53 years of marriage.

8 telephone poles cost $5 each = $40 dollars.

Brick - The interior and exterior red brick walls of the home were purchased by White for about a fourth of a cent each several years before he began construction of the house, representing a savings on this one item of 400 percent.

Brick cost a quarter of a cent each.

1 penny cost for 4 bricks

1000 pennies = 10 dollars cost for 4000 bricks

Bricks typically cost between $0.35 to $0.90 each, or about $350 to $900 per thousand bricks.

Back to top

Inside Pictures

.jpg)

.jpg)

.jpg)

.jpg)

Marble

that graces the fireplace mantle came a demolished Denver, Colo., bank building.

.jpg)

.jpg)

.jpg)

.jpg)

The

Chris White awards wall

.jpg)

.jpg)

Back to top

The Family Tree

The Family Tree is displayed in the Octagon house. The information in the Family

Tree was researched by Mary Lou White Morris. There are 640 name on the

printed Family Tree. The oldest relative dates from 1125.

.jpg)

.jpg)

Chandelier

Perhaps the things that best reflects White's past profession and Western Oklahoma heritage - he grew up at Geary in Blaine County is the chandelier he made from three old steel implement wheels:

One came from a 1-horse lister used years ago by his father Losson I. White, to prepare ground for planting.

Others came from cultivators and he also used truck mud chains and colored glass bottles in the fixture.

Back to top

News

Stillwater News-Press Home Scene

and 1980 WORLD - TULSA, OKLA. Unusual House Built From Odds And Ends TULSA PAGE

8, COUNTRY. WORLD, NOVEMBER 9, 1980 By STEVE FORSYTHE Stillwater

.jpg)

.jpg)

Chris and Lydia Travel Pictures

Back to top

Before Lydia married Chris, her family traveled. There are pictures of Grand Canyon, Arizona, Colorado, Yellowstone, Idaho, Nebraska, Kansas, Arkansas, Chicago, Florida.

Here is Lydia in California

.jpg)

Chris and Lydia Travel Pictures - Page 0

Chris and Lydia did most of their traveling in the 1960s. They went to

more than 40 countries. Including Asia, Middle East,

Europe in a mini-van and the United States in camper.

Camping with the Rolling Rockers

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 1

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 2

1960 - 1961 Chris and Lydia lived in Bangkok, Thailand For two years (1960-1961)

Chris taught agriculture and they traveled to many countries.

On the way to Thailand they stopped in these countries:

Hawaii,

Philippines,

Singapore,

Malaysia,

China Hong Kong,

Cambodia (They traveled here a couple times when they lived in Bangkok).

This is Chris and Lydias house in Bangkok, Thailand

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 3

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 4

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 5

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 6

This picture is Lydia doing a charcoal rubbing on the temple.

It is illegal to TOUCH the temple now. These rubbings are priceless.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 7

Teaching a class on how to use a pressure cooker. Notice the cooker is

hanging from the ceiling!

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 8

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 9

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 10

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 11

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 12

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 13

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 14

They traveled to Cambodia a couple times when they lived in Bangkok.

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 15

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 16

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 17

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 18

1961

Chris and Lydia traveled in a mini-van for a months. This list is from Mary Lou’s August 1961 calendar

Lebanon Beirut August 3, 1961

Israel Jerusalem August 6

Egypt Cairo August 8

Egypt Luxor August 9

Egypt Cairo August 10

Turkey Istanbul August 11

Greece Athens August 12

Italy Rome August 13

France Paris August 15

Germany Frankfurt August 17

.

This is the Jerusalem Airport in 1961

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 19

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 20

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 21

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 22

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 23

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 24

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 25

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 26

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 27

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 28

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 29

1967 Trip with Chris and Lydia to move Mary Lou and Milt family back to USA.

Fly from Santiago, Chile to Buenos Aires, Argentina.

Bus to Sao Paulo, Brazil. Board Moore-McCormack Lines, Mormacisle freighter ship.

Cruise to Rio de Janeiro, Recife (NE Brazil), Barbados, Caribbean.

Got off the ship in Jacksonville Florida but could not find a car to buy.

Sailed on to Savannah, Georgia

Got off in Charleston South Carolina. Milt bought 1960 Pontiac Bonneville.

Drive to Oklahoma. Fuel filter problem. Milt bought tools and a new filter at Sears, installed it in the parking lot. Then we continued driving to Oklahoma.

Drive to St. Paul Minnesota where Milt paid $35,000 cash for the Shorewood Drive house.

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 30

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 31

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 32

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 33

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 34

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 35

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 36

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 37

.

.jpg)

Back to top

Chris and Lydia Travel Pictures - Page 38

.

.jpg)

aa

bb

This page and all other pages in the

http://www.mytrips.com web site, along with the journals, images, and photos are Copyright ©

2025 by Suzanna Travels. All publication rights are reserved. Email: web@

mytrips.com Remove the space after the @

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)